Workmanship Check

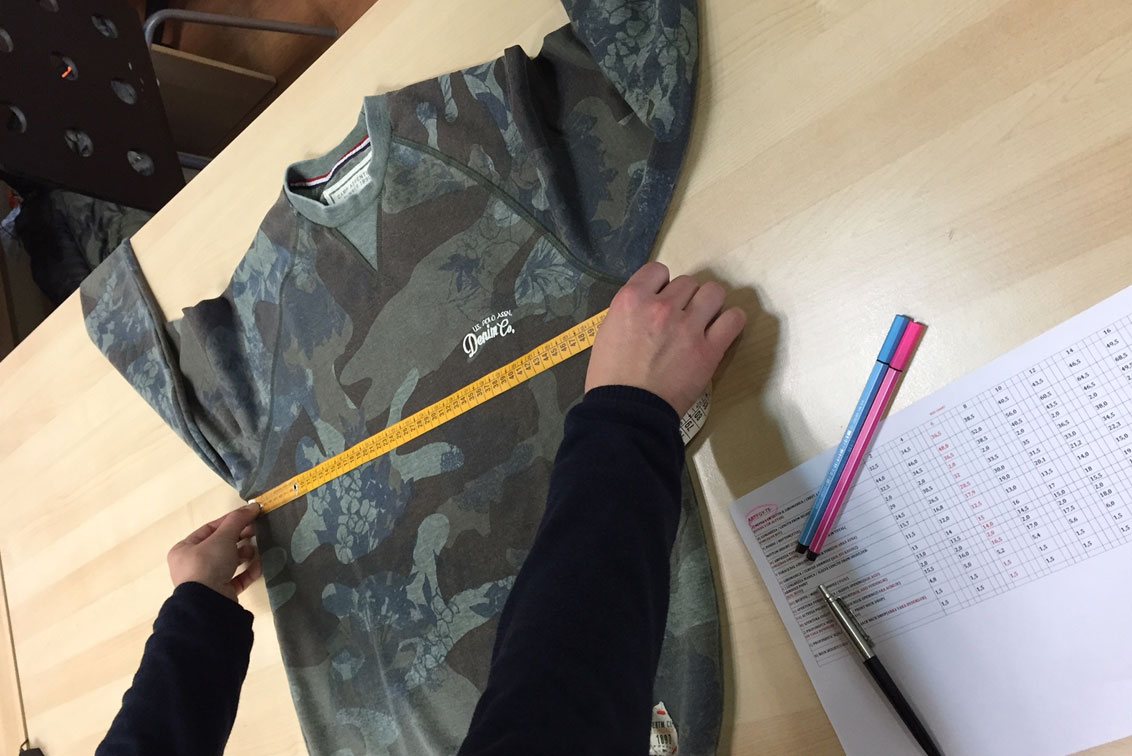

The products are randomly pulled as per the sample size, the QC will check the products visually against customer approved sample or contract specification and all non-conformities

Acceptable Quality Level

Generally for the workmanship check, Internationally most widely followed AQL - Accept or Reject criteria for consumer goods

Why FRI?

Findings in the Final Random Inspection can help you to know about your shipment when the shipment is still at manufacturing location like;

- Information on Product Quantity and Quality.

- Compliance with the specifications (PO, Style, Measurements, Labeling& Markings, Functionality, safety and regulatory requirements etc.,)

- Nature and percentage of defects in the shipment.

- All this advance information gives advantage to;

- Avoid last minute surprises in shipment & helps to take correction where necessary in timely manner.

- Avoid / minimize business risks like costly recalls / corrections in the destination / Import Country.

- Maintain the positive Brand value and integrity.

Is it necessary to do FRI for all your deliveries?

Yes, it is always suggested to have Inspections in all shipments. This helps keep monitoring on the factory's quality level.

Critical situations where Inspection is Must;

- In case of the value of shipment is higher and quantities are more.

- When you are making 100% advance payment prior to receiving merchandise.

- While working first time with the factories.

- If you have faced any quality issue with particular factory in the recent past shipments or their submitted samples.

- High Risk - Regulatory / Safety products Example Infants / Kids.

Disclaimer - Inspection is not Insurance or guarantee for all quality related issues, it is a tool with certain risk factors due to Random sampling & statistical methods.